Nikel2

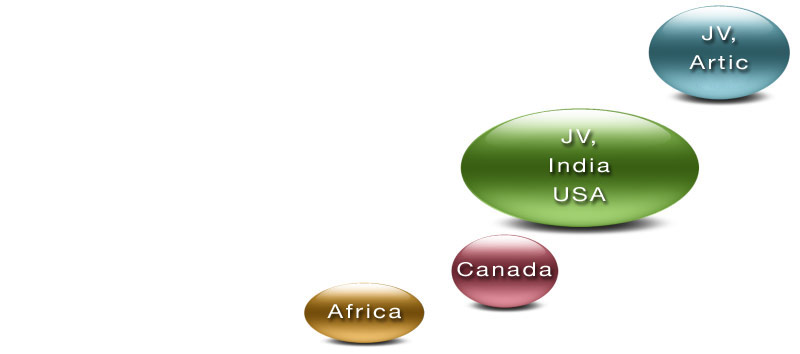

Nikel2 is new expro gas company dedicated to non conventional gas resources that is a subsidiary of GEOTECH D group. Resources of this latter are including:

- Oil/gas and Mining division with assets in Canada,

Australia and Africa.

Versus funded capex, the exploration programs of this group are

largely successfull due to a permanent low cost approach on opex.

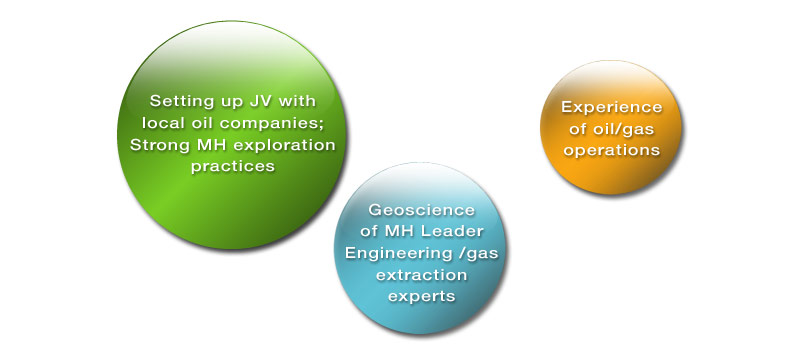

Thanks to a large experience in geoscience supported by

geoscientists of TelesioGalillei academy.

- Gas fields: Wharfresources plc,

Domepetroleum, Phoenix, Allied oil, Jurassica …

Wharfresources is starting the first gas processing line of its

gas processing facilities and pipelines from the 1st Gingin well

(ep389) is part of JV onEP389 that discovers a conventional and

huge shale gas field 37TCF certified - min 60TCF expected that

makes 72Bus for Wharfresources.

- Mining assets: significant Australian resources of Yellowenergy, Allied gold, DNIMines, DNIMetal in Canada … are Uranium, Thorium, Gold, Silver (see ex: websites:Yellow Energyplc.com).

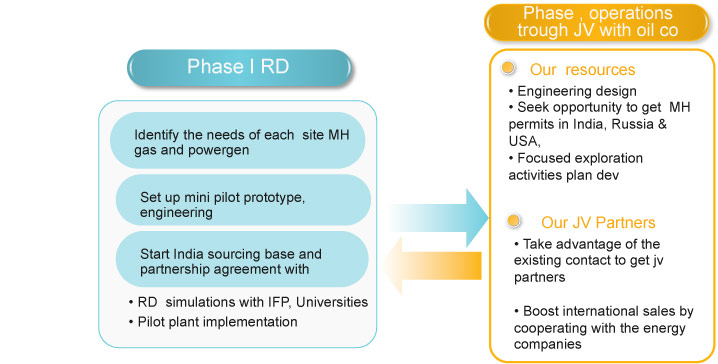

Within our R&D team there are two delivery arms:

Exploration consists of both Generative Exploration and Near Mine Exploration. Generative Exploration makes discoveries by leveraging our land position in the world's most prospective domains, while our Near Mine team supports the production and growth of those discoveries by providing reserve replacement and optimizing existing land position near our world-class districts.

Business Opportunity Delivery manages the projects from opportunity creation in the early stage studies through project development to ensure safe, on-time, on-budget and fit-for-purpose delivery into commercial production in partnership with our operating regions.

The delivery arms are supported by three enablement teams:

- Solutions & Innovation

- Business & Planning Services

- Value Assurance

These teams provide technical expertise, functional leadership, as well as project, portfolio and business planning across all stages of the pipeline, focusing on driving innovation and business effectiveness.